| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Place of Origin : China

MOQ : 1

Price : $55-62

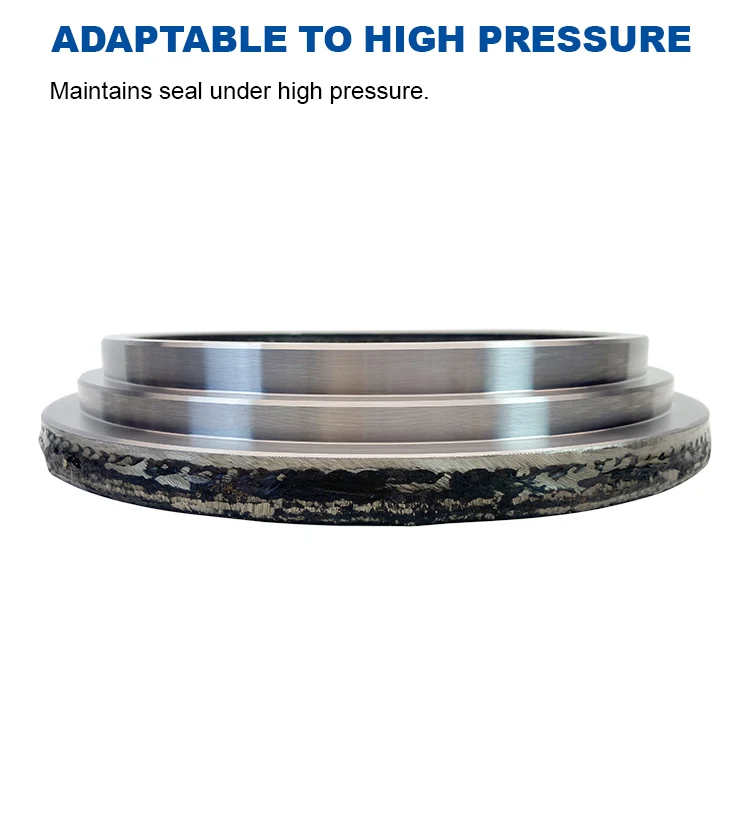

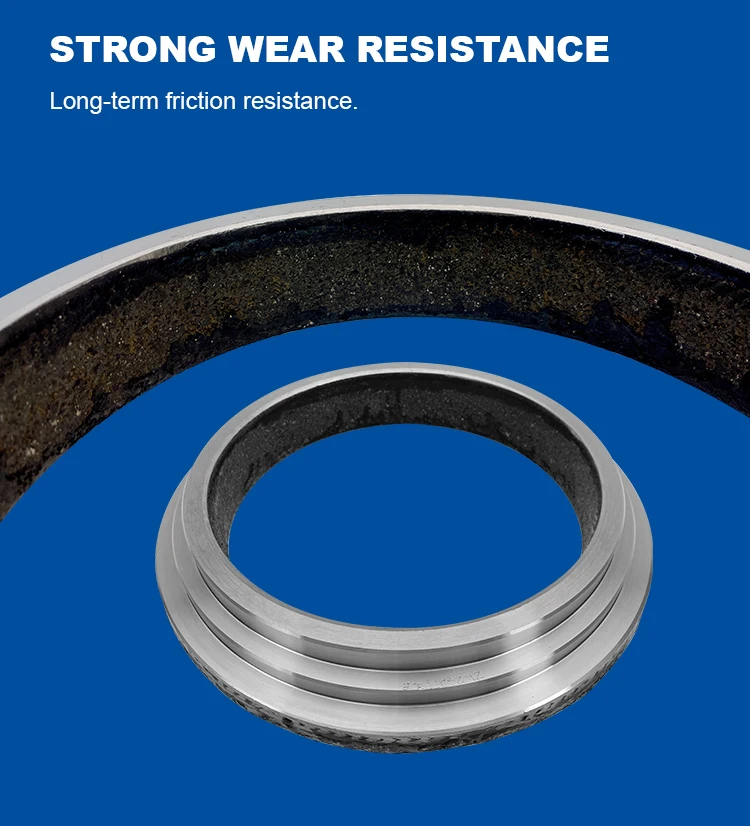

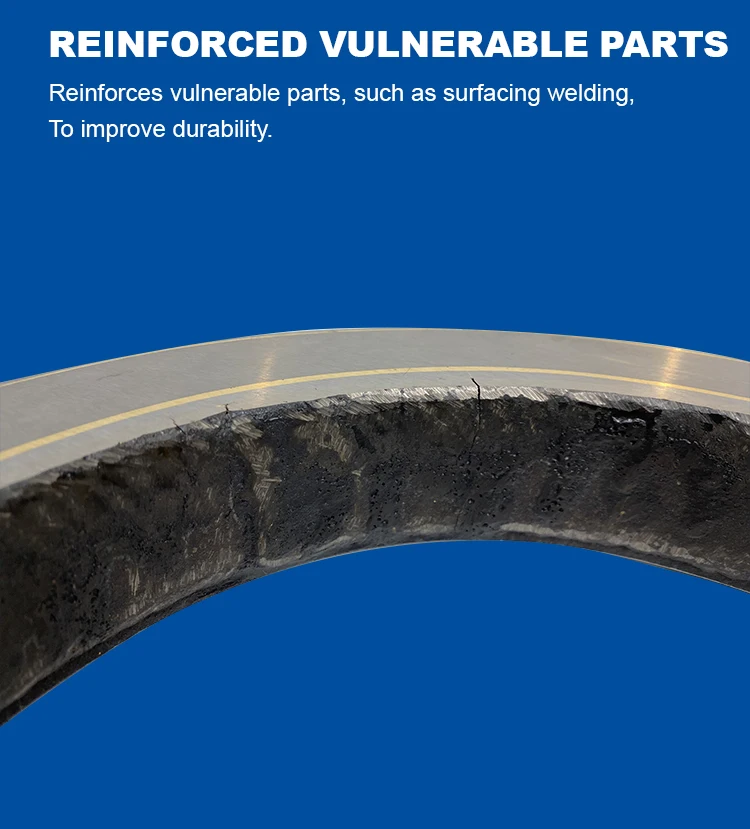

Material : Tungsten carbide, Alloy

Type/Size : DN200/230/260

Carbide thickness : 15+5mm / 15mm

Carbide hardness : HRA ≥85

Electrode hardness : HRC ≥65

Weight DN200 : 7.92 kgs

Weight DN230 : 8.3 kgs

Weight DN260 : 8.1 kgs

MOQ : 1 piece

Delivery time : 5-15 days

Wear plate type : Single/Double/Full Alloy

Item no. DN200 : 590654/590660

Item no. DN230 : 500012/590129

Item no. DN260 : 500008/590165

Product type : Cutting rings

item no./size | weight(kgs) | Material |

590654/590660(200) | 7.92 | Carbide HRA:≥85 Electrode HRC:≥65 |

500012/590129(230) | 8.3 | Carbide HRA:≥85 Electrode HRC:≥65 |

500008/590165(260) | 8.1 | Carbide HRA:≥85 Electrode HRC:≥65 |

|

|

DN230 Concrete Pump Wear Plate with Dual Carbide 15+5mm and Single Carbide 15mm Options for Wear Resistance Images |